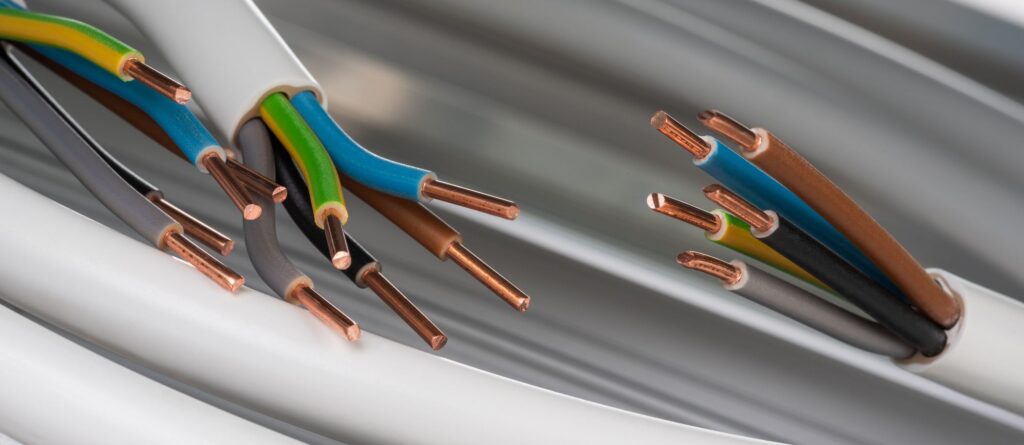

A strong cable industry means a sustainable cable industry: but what does this look like?

The electrical industry in Australia is a significant and critically important sector of the construction industry. Approximately 50% of all cables used in Australia are locally manufactured — an impressive feat in today’s world.

The Australian cable industry plays a vital role in the nation’s infrastructure and must identify key priorities and take action throughout the supply chain to ensure that it is reliable and sustainable into the future. These priorities span environmental responsibility, safety and workforce wellbeing.

Key areas of focus for a sustainable cable industry

Environmental considerations

The industry must address several environmental factors, including:

- choice of raw materials

- energy consumption during manufacturing

- longevity and end-of-life disposal of products

- overall carbon footprint.

Safety measures

Safety is crucial at every stage of the cable lifecycle, from manufacturing and storage to transportation, installation, and disposal.

Workforce wellbeing

Ensuring the ability to attract and retain skilled staff, maintain their safety, and support their overall wellbeing is essential for sustainable operations.

The role of the Australian Cable Initiative

The Australian Cable Initiative (ACI) represents cable manufacturers, both local and international, as well as wholesalers and installers of electrical cables. The organisation works with members on multiple factors affecting the industry’s reliability and sustainability, including:

- Product design and manufacturing that prioritise performance, safety, compliance with standards, and recyclability within a circular economy framework.

- Environmental considerations such as reducing CO2 emissions, landfill waste, and grid-drawn energy consumption during manufacturing.

- Workplace health and safety throughout the supply chain.

- Staff wellbeing and respectful engagement with customers.

Recent industry initiatives

Product design and manufacture

The Australian cable industry has a history of innovation. It led the global market in eliminating lead from the PVC compounds used for building wire insulation — an initiative that improved installer safety. More recently, manufacturers have been evaluating new materials that enhance performance and fire safety.

Standards compliance and safety

Cable products in Australia must comply with rigorous Australian standards developed to ensure safe installations when following AS/NZS 3000 (The Wiring Rules) and AS/NZS 3008 (Electrical Installations – Selection of Cables).

ACI members commit to upholding the ACI Charter, which mandates compliance with these standards through certification and ongoing surveillance testing. The ACI’s Surveillance Scheme randomly tests cables from the market, ensuring compliance by both members and non-members. Notably, the scheme identified the defects in the infamous Infinity and ECables, prompting a mandatory safety recall by state electrical safety authorities.

Recycling and the circular economy

Contractors often face challenges with recycling cable spools and short cable remnants. ACI members are developing a pilot scheme that allows contractors to return spools with residual cable for credit. These materials are then properly recycled, with different components segregated for appropriate treatment, maximising reuse and supporting a circular economy.

Environmental impact tracking

ACI manufacturing members are already tracking key environmental metrics, including CO2 generation, landfill creation, and grid-drawn electricity consumption. Data is normalised on a per tonne of product manufactured basis, with each individual company able to track their own performance against the cohort, encouraging best practices and performance improvements.

Workplace health and safety

A safe working environment is essential for maintaining reliable and sustainable operations. Companies that neglect workplace safety risk fines, closures, and workforce dissatisfaction, ultimately leading to higher costs and supply disruptions. ACI members are committed to proactive safety monitoring and improvement. Special attention is given to the handling of large cable drums, which pose unique safety risks. ACI members are available to provide advice on all aspects of supply chain WHS.

Staff wellbeing

Many ACI members have wellness programs to support employee health and motivation. These initiatives are increasingly recognised as valuable for improving employee engagement and delivering better outcomes for customers.

The Australian cable industry’s focus on innovation, environmental responsibility, safety, and workforce wellbeing positions it well to remain strong, reliable, and sustainable into the future.