ENSURING YOU’RE USING COMPLIANT CABLES IS ESSENTIAL — BUT WHAT ARE THE SIGNS TO LOOK OUT FOR, AND WHAT DO YOU NEED TO KNOW? THE AUSTRALIAN CABLE INITIATIVE (ACI) EXPLAINS IT ALL.

Did you know that not all electrical cables sold in Australia meet the strict Australian standards set to ensure safety and performance? While these standards exist to protect people and property — primarily by reducing risks of electrocution and fire hazards — some cables on the market have fallen short.

Compliance isn’t just a box to tick; it’s a vital measure for safety. Installed cables are usually hidden in walls or ceilings, making them difficult, if not impossible, to access once a building is complete. If a non-compliant cable needs replacement after construction, the task can be both disruptive and extremely costly. In fact, the cost of replacement often far exceeds the value of the cable itself, as the work may require opening up walls or ceilings, rerouting, and refinishing.

The consequences can be dire. Take the widely publicised Infinity/Olsent cable case. When these cables were found to be faulty, the supplier went into receivership, leaving installers and homeowners with little chance of compensation. Some distributors stepped up, but in many cases, the financial burden fell on the electricians who had installed the faulty cables, as the recall was mandatory.

WHY AREN’T ALL CABLES IN AUSTRALIA COMPLIANT?

In Australia, ensuring electrical cable safety and compliance is a multi-step process, coordinated by the Electrical Regulatory Authorities Council (ERAC). ERAC oversees the Electrical Equipment Safety System (EESS), which classifies electrical equipment used in homes based on risk. Products that are “in scope” are listed in AS/NZS 4417.2. Building cable, which is used inside homes, is considered a Level 3 in-scope product, meaning it must meet the highest standards for safety.

Once certified, Level 3 cables must be registered on the EESS database and marked with the Regulatory Compliance Mark (RCM) as proof. While all certified cables sold in Australia should meet these strict requirements, non-compliant cables still occasionally make their way into the market. Here’s why:

Compliance risks

To gain certification for a cable, the manufacturer or importer is required to submit a sample for testing by a certified test lab. Once the cable is certified it may not need to be re-certified for as long as five years. During this time, things can change in the manufacturing process that could result in the cable becoming non-compliant.

The Australian Standards have a requirement that all products are routinely tested throughout their production life to ensure they remain compliant. The local cable manufacturing industry, which makes about 50% of Australia’s cable requirements, has this routine testing requirement embedded in its quality systems, granting a high level of assurance that cables continue to be compliant to the relevant Australian standard.

Even a minor alteration, like substituting a material or switching production lines, can compromise safety. The

Infinity/Olsent brand is a high-profile example where a seemingly minor change led to a mandatory recall by the Australian Competition and Consumer Commission (ACCC) after it was discovered that the insulation deteriorated dangerously over time.

Gaps in ongoing compliance monitoring

Unfortunately, Australian state-based regulators lack the resources to constantly monitor whether cables remain compliant after their initial certification. This is where issues can arise, as initial tests alone can’t guarantee the long-term safety of a product if there are changes in manufacturing processes.

THE ROLE OF THE AUSTRALIAN CABLE INITIATIVE (ACI)

To address these gaps, the ACI was established to run an independent surveillance program, regularly purchasing cables from the marketplace and testing them for safety. This proactive approach helps identify and remove non-compliant or unsafe products before they become widespread. The ACI tests cables from a broad range of manufacturers, ensuring both member and non-member products are held to the same high standards.

With these safeguards in place, Australian consumers can feel more confident that their cables meet high safety standards. For more information on ACI’s surveillance program, visit the australiancableinitiative.com.

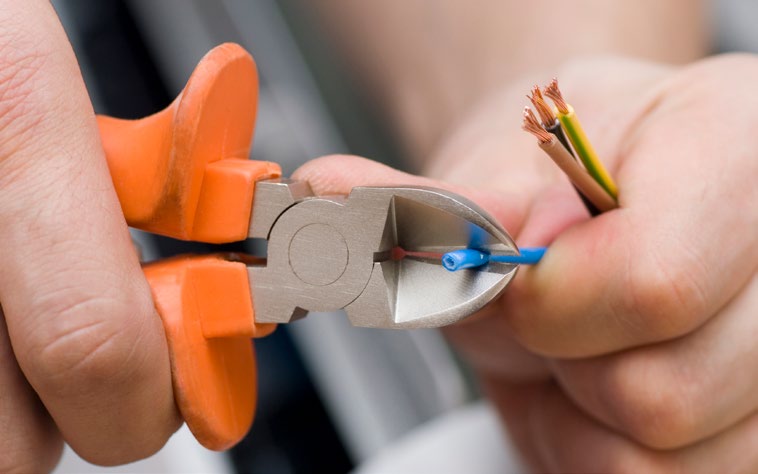

HOW TO SPOT NON-COMPLIANT CABLES

Identifying whether a cable is safe and compliant isn’t always easy — many cables look similar, even if they don’t meet the same standards. But there are a few steps you can take to check if a cable is up to code:

Confirm if it’s “in scope”: First, check if the cable is an “in-scope” cable, as defined by the AS/NZS 4417.2 standard. The EESS website – eess.gov.au –provides a list of Level 3 in-scope products.

Look for the Regulatory Compliance Mark (RCM): The RCM is a quick indicator of compliance. Check if it’s printed on the cable or the packaging.

Search the EESS database: You can perform a public search on the EESS database to confirm if the cable is certified. Simply enter the product details on the website to verify its compliance status.

Still unsure? Ask the experts: If you’re still uncertain after completing these checks, the

ACI may be able to help.

Visit the ACI website — to report the cable, and they can let you know if there are any concerns with the product